Carbon Dioxide (CO2) Blast Cleaning: also known as Dry Ice Cleaning, Cryogenic Cleaning, or Dry Ice Blasting

Dry ice blasting (or cryogenic cleaning) is an efficient and cost-effective industrial cleaning system. The cleaning method helps industries to maximize production capability and quality. Dry ice blasting uses soft dry ice as a medium that is accelerated to supersonic speeds in a pressurized air stream to impact a surface being cleaned or prepared. The resulting mini-explosions on the surface lift the undesirable item off the underlying substrate.

Dry ice blasting uses a combination of kinetic energy, thermal shock, and sublimation effects to effectively clean a surface. Please refer to video below:

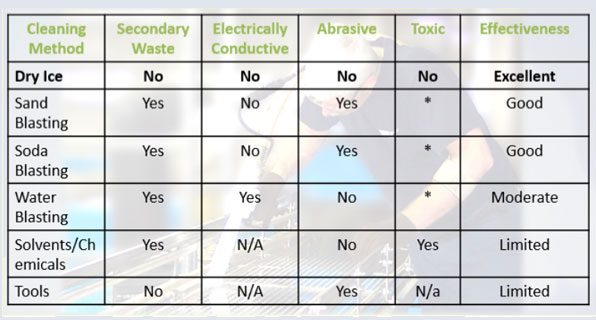

Dry ice cleaning as an industrial cleaning solution has many advantages over other conventional cleaning processes as shown in the chart below:

Carbon Dioxide (CO2) Blast Cleaning Applications

PLASTICS

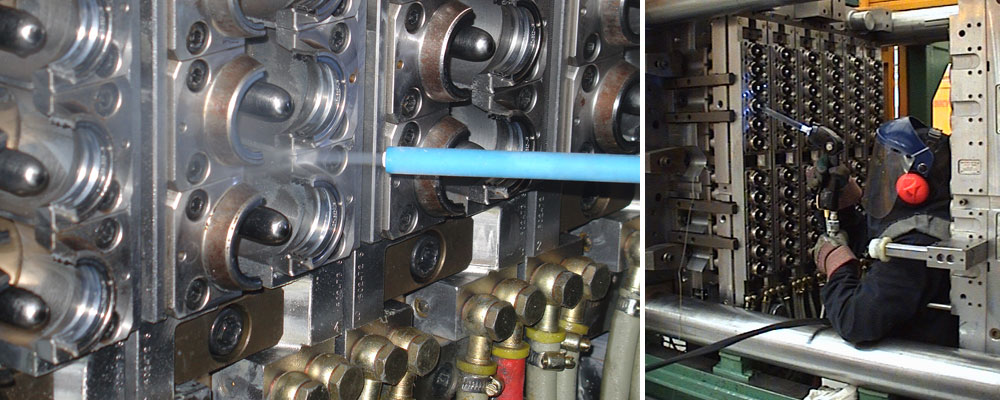

Clean mold cavities and vents are a major concern for plastic part manufacturers in maintaining today’s high quality standards. Molds and the plastic coming into them are heated to extreme temperatures. This generates a gas that liquefies and sticks to the mold which can be tough to remove. The build-up of unwanted surface residues from either the resin additive off-gases or the use of mold releases can create various problems… ranging from unwanted product release, inferior product quality, and possible damage to tools. Additionally, vents at the end-of-fill get clogged from the buildup of gases. Flash, burns, and short shots on the product can be caused by clogged vents. These vents need to remain open and unobstructed in order to help keep the mold clean.

In addition to being very labor intensive, traditional cleaning such as abrasive blasting, wiping with chemicals or solvents, and wire brushing requires production to stop so molds can be taken out and disassembled. With dry ice blasting, molds can be cleaned at hot operating temperature and in-place… without the use of water, chemicals or creation of secondary waste. This greatly reduces, and often eliminates downtime due to cleaning.

RUBBER

A major problem faced by rubber molders is mold fouling. This is caused by the rubber off-gassing in the cavities at the vent area. Build-up of cured material and mold release agents causes molds that stick, blemishes, and unwanted flash on final parts… making them unusable and requiring line shutdown for cleaning. This results in subsequent productivity loss when molds are taken out of the press for cleaning. In some cases, mold build-up can lead to over-packing, which in turn can cause internal strains to the tooling.

Traditional cleaning methods such as manual scraping or glass bead blasting can be time consuming, ineffective, damaging to molds and result in increased downtime. Dry ice cleaning allows for in-place cleaning – without major disassembly or cool down. Dry ice blasting uses non-abrasive dry ice that does not damage molds. Furthermore, potential damage to the molds from removing them from the press and reinstalling them is reduced.

Dry ice blasting is used to clean rubber molds for manufacturers of tires, gaskets, o-rings, shoes, and many other products.

FOUNDRY

Cold Jet dry ice blasting has cut mold and core box cleaning time by 60% for aluminum permanent molders:

- Removing residue with kerosene is ineffective when trying to clean contamination that gets trapped in the loops and corners of a mold. Dry ice blasting provides a superior cleaning tool for permanent mold cleaning because molds are cleaned hot and in-place.

- The resin used in the core box process creates a chemical change that activates a gas that hardens quickly and forms a bond with the sand in the core box. While the majority of this mixture is removed during shakeout, what remains can be difficult to remove. With dry ice blasting contamination can be easily removed from hard to reach places. Tools from the core-making machine can be cleaned in place with dry ice cleaning, allowing for greater production efficiency.

Other common applications in the foundry shop include:

- Cleaning graphite lubricants off die-casting machines

- Removing excess grease, dust, ink or carbon off production equipment and hydraulic power units

- Cleaning conveyors without damaging pneumatic devices, bearings or electrical equipment